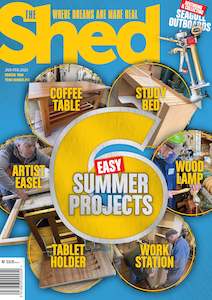

The Shed 106, January — February 2023

For this issue of the magazine, we thought it would be an idea to keep our readers busy and enjoying themselves in their sheds on rainy summer days.

Our main article in this issue, “Six Summer Sheddie Projects", is about combining the fun of summer days and the annual wind-down with family and friends with the spirit of DIY that drove many of us to a self-sufficiency based around our garage workshops and sheds, and more recently extended into MenzSheds.

Our Kiwi number 8 wire mentality gave us pioneers such as Sir William Hamilton of HamiltonJet and Peter Witehira of Power Beat with his never-go-flat battery.

Now, it’s your turn. We’ve come up with six projects of varying levels of skill, and invite you to have a go at them, or — better yet — put your ‘I can do that’ hat on and improve on them.

The workstation

This was the most complex project, and isn’t necessarily for the faint-hearted. It took two guys four months to complete, partly because it changed over that time. It was originally going to be wall mounted with a fold-up desk. However, the weight of the MDF meant that actually mounting it on a wall was going to be a challenge, and coming up with a fixing method that was both sturdy and easy to change should the need to do so arise, proved to be ambitious.

Coffee table

The idea behind this coffee table was for it to double as storage space for children’s books and toys. We considered drawers and even a lift-off tray, but drawers can jam unless proper slides are used — and this increases the cost and skill level required. The timber for the top was too heavy to be lifted and carried around. The screws for the hinges turned out to be the only screws in the whole project, with everything else being glued and biscuit-jointed or glued and dowelled.

The lamp

This was my writer Nigel Young project, and I started by going through the timber rack at our MenzShed, looking for different colours and sizes, as the plan was to laminate them together and then have the base and lamp holder turned on a lathe.

I started by cutting a range of pieces into squares, then establishing the centre of each by drawing a line across the diagonals. The intention was to drill through each of them, and then pass a 6mm dowel through them all while also glueing them all together. Before drilling them, however, I used a compass to draw the best circle I could out of each of them. Next, I used a bandsaw to cut out each circle as closely as I could — not one of my strengths but I got them pretty close.

Painter’s easel

We had been thinking about this one as a potential stand-alone how-to article for The Shed in its own right, after seeing the size of them in an arts store — all very nice, but where do you keep them as they can take up quite a lot of space. So, the main criterion for this was to be able to use it and then fold it away with minimal storage requirements.

The bunk and desk

This project was a similar size to the workstation, the difference being that the employee who used that was able to walk away from it at the end of the day. With the bunk desk, however, the user was required to sleep at their station — no sneaking off for a life somewhere else.

Tablet holder

This was built by a sheddie who had retired from the world of IT, and who had the analytical tools to sit down and write himself a brief. The tablet holder needed to be able to rotate as well as be raised up and down, so he started with some questions and observations:

Why would one want a tablet holder that needed to be able to rotate as well as be raised up and down …

Build a small trailer, part two

At the end of part one ( The Shed , November–December 2022, issue 105), we sent the welded frame, the front and back gates, and the axle of our trailer for galvanising. You could paint the trailer instead of galvanising it, but paint won’t get deep inside the box section to stop rusting in there. You can paint the frame after galvanising, but there’s a lot of fuss with primer and preparation.

My shed — Murray Brown

It has been said that the first law of intelligent tinkering is to save all the parts. That is exactly what Cambridge sheddie, Murray Brown, has been doing since he was a nipper. Murray is a mechanical engineer, wood turner, and self-confessed hoarder. When I arrive to check out his growing fleet of home-built tractor models made from upcycled sewing machines, I somehow lose an hour just nosing around the first two sheds of his eight-shed property.

Alibre 101, part three

This issue contains part three in our se