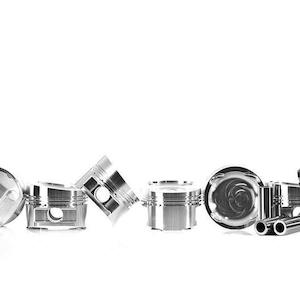

JE Forged Piston Sets | Fits VW 3.2L 24V VR6 Engines

JE piston sets are a drop-ship item, expect a 1-4 week lead time. A SERIOUS VR6 PISTON FOR SERIOUS USE

Building a high powered race engine for road race, drag race, or full out competition racing? JE Pistons for your VW 24V 3.2L VR6 engine offer the ultimate in strength and reliability in a forged piston. LEADING PISTON FEATURES

- Ultra-high performance forged piston set

- Optional bore sizing

- Optional NA or boosted compression ratios

- Includes JE Pro Seal piston rings

- Includes wrist pins and pin locks

- No dish deburring or preparation needed

- Individually prepared inspection report of dimensional conformity

- Each piston individually serialized for complete traceability

- 23-point post-production inspection conducted by certified personnel

- Tighter tolerances on 14 critical areas of the piston

- All critical surfaces machined in dedicated Critical Manufacturing Cell INCLUDED IN PISTON SET

- 6X JE forged VR6 pistons

- 6X JE Pro Seal piston rings sets

- 6X JE straight wall carbon steel wrist pins

- 12X JE wrist pin wire locks COMPRESSION RATIO

JE piston sets for the VW 3.2L VR6 engines are offered in various compression ratios. Lower compression pistons (8.5:1) are typically used on boosted engines, resulting in less chance of knock and cylinder detonation than higher compression ratio pistons. Lower compression will sacrifice out of boost power, spool time, and power/torque per pound of boost. Choose your compression ratio accordingly. For naturally aspirated engine builds we recommend using a higher compression ratio piston (11.5:1). Speak with your engine tuner about the fuel and boost pressure used to determine the best compression for your engine. BORE SIZE

JE offers your choice of bore size to suit your build. You have the option of stock (84mm) bore sizing,.5mm overbore sizing (84.5mm) or 1mm (85mm) oversized bores. Overbore pistons require additional machine work including a cylinder bore and hone, this work must be performed by a machine shop. For most performance engine builds, we recommend overboring the engine block when installing aftermarket pistons. This additional work ensures a proper piston to wall clearance and in most cases results in stronger compression, longer piston life, increased ring life, and quieter piston operation. MEASUREMENTS AND SPECIFICATIONS

Stock bore size:

Bore: 84mm

Stroke: 95.9mm

Rod size: 164X22

Dome CC's (8.5:1): -27

Dome CC's (11.5:1): -6.8

Weight (8.5:1): 328 grams

Weight (11.5:1): 342 grams

.5mm bore size:

Bore: 84.5mm

Stroke: 95.9mm

Rod size: 164X22

Dome CC's (8.5:1): -27.8

Weight (8.5:1): 334 grams

Weight (11.5:1): 348 grams

1mm bore size:

Bore: 84mm

Stroke: 95.9mm

Rod size: 164X22

Dome CC's (8.5:1): -28.6

Dome CC's (11.5:1): -7.9

Weight (8.5:1): 337 grams

Weight (11.5:1): 354 grams MANUFACTURING DETAILS

Forged from 2618 T6 aluminum

Engineered for extreme operating environments found in professional motorsport competition, JE manufactures this light yet strong piston from high tensile strength 2618 T6 aluminum. This high-performance alloy is suited for use with high compression ratios, high boost levels, and high octane usage tolerating acceleration forces of more than 8000 G's and directional changes exceeding 200 times a second while minimizing weight. This reliable forging is the ultra-high performance choice when building competition or very high powered boosted engine exceeding street power levels.

Optimized dish & dome design

The piston dish and dome have been individually designed to the combustion chamber of each individual application. Special care has been taken to provide properly placed valve reliefs as needed and feature smooth flowing radii across the surface for excellent flame travel. Designed and verified in JE's dedicated Critical Manufacturing Cell, providing reliable compression ratios and combustion characteristics.

JE Pro Seal piston rings

Every JE piston set includes a complete set of performance matching JE Pro Seal Piston Rings. JE Pro Seal rings are the result of over 60 years of experience in manufacturing racing piston technology such as NASCAR, ALMS, NHRA, and AMA. Pro Seal Ring features barrel-faced top rings made with premium ductile iron, plasma-moly inlays on the ring face combining nickel, chrome, and other trace elements. The second ring sets are taper-faced with a reverse torsional design and finished with a phosphate coating. These high-technology designs reduce friction, lower wear, improve ring seal, and extending ring